Where Do the Thread Go on Singer Touch Tronic 2010

PLEASE EMAIL ME AT duanesechser@hotmail.com or call me at 605-359-8939 If you have any questions or need help with anything I am here to help !

HERE IS SOME ANSWERS TO QUESTIONS ABOUT THE NEEDLE SIZE & THREAD TO USE WITH YOUR

SINGER 306, 319 AND SIMILAR Machines Where can I get a chart for 319w needle

size and thread size?

thank you,

duane

Dear Mr. Sechser,

Thank you for writing Singer. This household machine uses standard Singer needles.

You can use a 2020 for woven fabrics and a 2045 for knits. Most commonly used size

is a 14 for medium weight. Lighter fabrics could use either a 9 or 11. Denim uses

size 16. Please use general purpose weight thread. This type of thread is available at chain retailers such as Hancocks and JoAnn Fabrics as well as your local sewing retailer. Make sure not to use quilting weight threads in the machine as it will effect the tension. Singer Consumer Affairs Department SVP Worldwide.

HERE IS SOME ANSWERS TO QUESTIONS ABO UT THE NEEDLE SIZE & THREAD TO USE WITH

YOUR SINGER 306, 319 AND SIMILAR MACHINES Where can I get a chart for 319w needle size

and thread size?

thank you, duane Dear Mr. Sechser, Thank you for writing Singer. This household machine uses standard Singer needles. You can use a 2020 for woven fabrics and a 2045 for knits. Most commonly used size is a 14 for medium weight. Lighter fabrics could use either a 9 or 11. Denim uses size 16. Please use general purpose weight thread. This type of thread is available at chain retailers such as Hancocks and JoAnn Fabrics as well as your local sewing retailer. Make sure not to use quilting weight threads in the machine as it will effect the tension. Singer Consumer Affairs Department SVP Worldwide THREAD TENSION ISSUES

Hello, are you some of the many that are having problems with getting their thread tension set proper

or are having trouble getting the top thread tension adjusted to the correct tightness or setting. I have

helped several people in finding out what their problem was and most were to the point of just putting

the machine back in storage because they just could not get it to work.

I had a lady who had not sewed in many years she purchased a machine from me and when she got it

she set the machine up and threaded it put in a bobbin and began to sew. She noticed that the top

thread tension was not tight and so she adjusted the tension but it stayed the same so she went back

through the manual step by step and could not find the problem.

This poor lady was ready to pull her hair out, she emailed me and I gave a few suggestions still she

was still having problems, I gave more suggestions, to make a long store short it was that she had

her bobbin in backwards. I am going to tell you a few things to check if you are having problems

with the thread tension. 1. Thread weight in spool and bobbin may cause tension to be different

2. Make sure you have the machine threaded correct 3. Make sure thread is going through the

wire or spring correct on tension 4. Make sure needle is inserted correct flat side of needle facing

correct direction for the machine you are using (they are different) and that it is a new needle

or that it doesn't have a hook or point is flat, this can cause stitch skips and more problems.

5. Make sure the little finger on rotary is in space on needle plate; if this is not correct can

cause all kinds of problem.

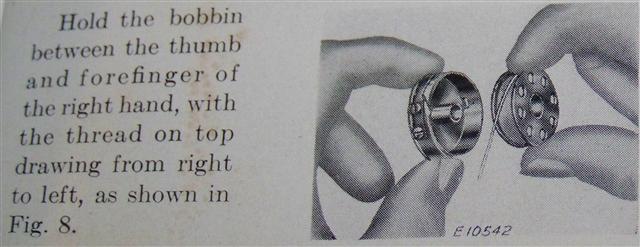

6. When putting the bobbin in the bobbin case make sure you put the bobbin in so the thread comes

off bobbin clock wise and that the thread is pulled into the slot on the spring of bobbin case if this is

not correct it will cause loose stitch because the spring is not doing its job. You may also need to adjust

the little screw on the bobbin case and I have received machines and the bobbin case has buildup inside the case and causes the bobbin not to turn free.

There are a lot of little things that can cause your tension not to work correct and cause loose stitch,

skip stitch, thread to bunch up so remember to look for these little things and if you are still having

problems make sure your machine is clean and that the rotary, bobbin case, thread tension parts are

not missing or have broken parts (I had one machine that the hook on the rotary had a very little

piece of the hook broken off). If you still can not figure it out I am willing to give it a shot just

email me or I am willing to take a look at your machine if you like.

I have parts available for your older Singer machines take a look at my website,

Also eBay;

I hope this helps, duane

IF YOU HAVE ANY QUESTIONS PLEASE CALL OR EMAIL ME!

I AM ABLE TO GET A LOT OF PARTS AND MAY NOT HAVE IT LISTED

BECAUSE OF THE TIME IT TAKES TO LIST ALL THE PARTS

call 1-605-359-8939

or email duanesechser@hotmail.com

Hello, if you're reading this you are having more problems and you have adjusted the thread

tension as far as it will go and the thread is still bunching up on the bottom of the material!

Y ou're really flustered and ready to pack the machine and put back in storage or throw it out,

well I am going to try and walk you through ways to fix this problem. We have to remember

that it is a machine and needs to be cleaned and maintained same as any machine. You take

your car in and have it looked at and have a tune-up so that it runs smooth and gets you from

point A to B right! 1. Check to make sure machine is threaded correctly Make sure you have

the thread in the disk going around and up through the spring tension up through the take-up

and down through the thread guides. 2. Check needle, some of singer machines insert with the

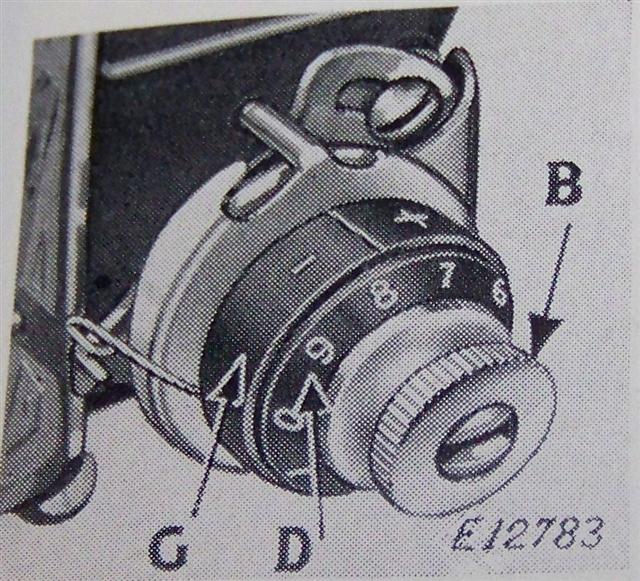

flat side of needle faces front of (Pictures from 1941 Manual Singer Manufacturing Co.)

machine, 15-, 201-2 221, 222, 301, and others and the 66, 99 and a few others are opposite, and

make sure needle is new or has no hooks or tip is not flat.

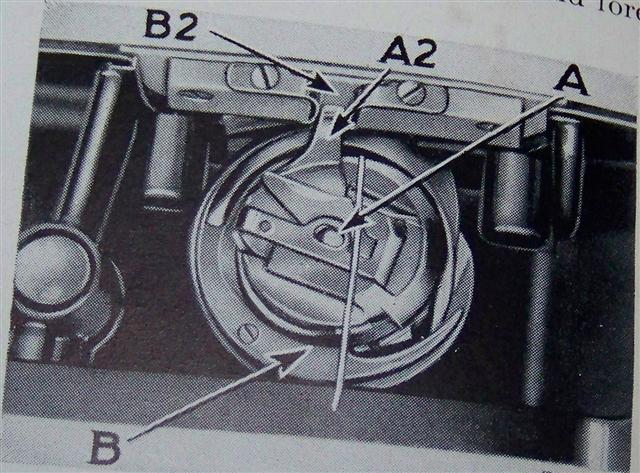

- Check rotary that the finger is in space on bottom side of needle plate

(B2 and A2)

and that the rotary hook is in great condition

and is free of thread. You may have to loosen the two set screw and remove rotary and take apart to

remove any thread that may be wrapped around it and put a drop of sewing machine oil on the moving

parts attach back to machine.

Make sure bobbin in bobbin case correct drawing string clockwise off of bobbin. Sew a few stitches

with tension set around 3 ½ - 4 on setting, if you still have thread bunching up on bottom side of

material we need to concentrate on the thread tension assembly. When you lift the presser foot

lever to up position does the thread tension release? Check your spring does it have good tension or

is it weak? When you turn the dial does it turn all the way or does it catch in spots before turning from

0-9? Ok, if all these check out and are working what we do next, I have found that the thread tension

is a touchy part we may need to take it off the machine and clean & re-adjust it.

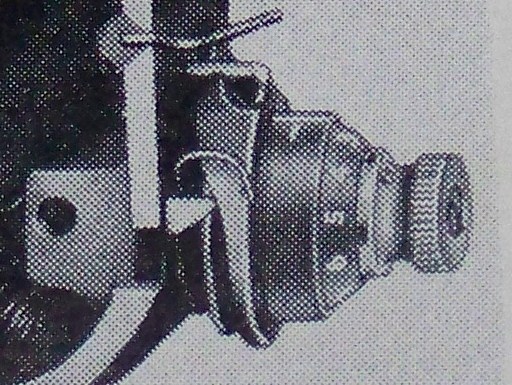

Take off the face plate and loosen the set screw, take off the little screw holding the chrome thread

guide to the tension assembly and take a screw driver and insert into tension with fingers pull lightly

towards you while turning tension back and forth with screw driver (If your not comfortable doing this

then you may have to take to repair shop) until you have it removed.

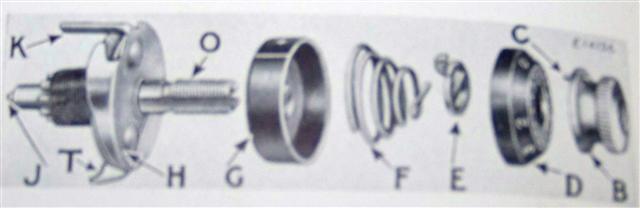

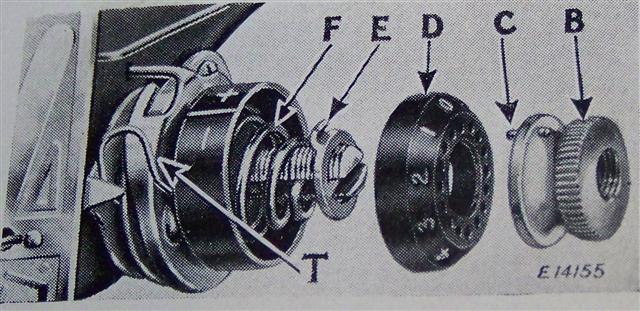

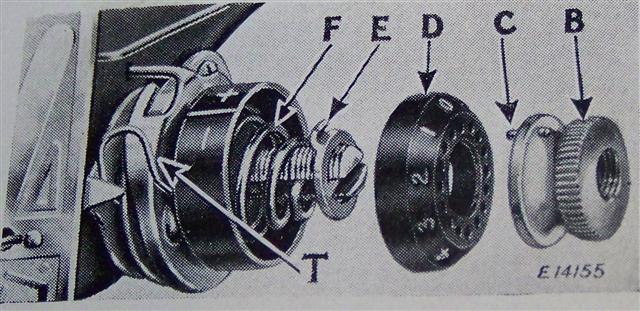

The first thing to do is if you have a manual get it out it has a picture of the tension and its parts, have

this handy in case you are unsure of how it goes back together. Now, since you have it out clean the

machine area of tension first then take apart the assembly by unscrewing the thumb nut and lay out

the parts in the order they go back on.

Clean the parts as needed from dirt or oil build-up

If your not comfortable doing this take to repair shop.

When you have cleaned it and all parts look to be in good shape put back together but before putting

back in your machine check the spring "T" to make sure there is some tension and that it is working correctly.

If it doesn't feel to have any tension or is light you can pull the spring up and adjust to the left one tooth

or as needed.

I just had a machine that I was sewing with and when I turned over the material I was sewing,

the top thread had made a mess on the bottom side. I adjusted the spring and it fixed the problem

and the machine sews great now. If your machine is clean unlike this tension which as you can

see is dirty needs to be cleaned but adjusting the spring fixed the machine. There are so many

things that can cause problems and you just need to take the time and clean and adjust these

parts and your ready to sew, I know that not everybody is comfortable doing this but it is an easy fix.

There is one more thing if this doesn't fix the problem the part "E". I have seen the center of this

maybe bent out and is causing the tension pin "J" not to protrude out far enough to work proper and

may need replacing. This usually happens from pulling up to hard on pressure release lever. Take it

off machine and lay on bench take a small punch and lightly tap it towards the direction of the

machine will fix the problem but be sure not to hit to hard or you will break it. I hope this was helpful,

duane

IF YOU HAVE ANY QUESTIONS PLEASE CALL OR EMAIL ME!

I AM ABLE TO GET A LOT OF PARTS AND MAY NOT HAVE IT LISTED

BECAUSE OF THE TIME IT TAKES TO LIST ALL THE PARTS

call 1-605-359-8939

HOW TO ATTACH YOUR SLIDE PLATE

TO YOUR SINGER 66, 99, 185 AND ANY OTHER SIMILAR MACHINE

SLIDE PLATE INTO POSITION RIGHT TO LEFT

LIFT FOOT AND NEEDLE TO KEEP OUT OF THE WAY

SLIDE PLATE TO THE LEFT

MAKE SURE PLATE IS FACING CORRECT DIRECTION

YOU MAY NEED TO RAISE THE FLAT SPRING JUST A

LITTLE TO LINE UP WITH THE GROVE ON BOTH

SIDES OF THE PLATE DO NOT LIFT TO HIGH OR YOU

WILL SNAP THE PLATE SPRING

ONCE LINED UP SLIDE THE PLATE LEFT

ONTO THE SPRING

I HOPE THIS HELPED THOSE WHO FORGOT OR

DIDN'T KNOW HOW

TO PUT ON THEIR SLIDE PLATES

I HAVE HAD A LOT OF REQUEST ON HOW

TO PUT ON THE SINGER

66, 99, 185 AND OTHER SLIDE PLATES

PACKING YOUR MACHINE FOR

SHIPPING

HELLO, I AM GOING TO TELL YOU HOW TO PACK YOUR SEWING MACHINE FOR SHIPPING

TO THE NEW OWNER OR JUST TO MAKE THE MOVING TRIP SAFE! BE SURE TO UNPACK

DO NOT LEAVE MACHINE PACKED FOR A LONG PERIOD OF TIME IT NEEDS AIR TOO.

THERE ARE DIFFERENT WAYS OF PACKING YOUR MACHINE, I AM GOING TO SHOW YOU

HOW I PACK AND HAVE HAD GREAT LUCK WITH IT. DEPENDING ON THE MACHINE AND

THE SIZE OF THE CASE WILL MATTER ON HOW MUCH PACKING YOU USE, I USE BUBBLE

WRAP AND PEANUTS BUT IF YOU DON'T HAVE THAT THEN USE WHAT YOU HAVE.

THE MAIN POINT HERE IS THAT YOU DON'T WANT THE MACHINE TO BE ABLE TO

MOVE AROUND DURING SHIPPING, THAT IS WHAT DAMAGES THE MACHINE AND CASE.

THE FIRST THING YOU CAN DO IS TAKE OFF THE SPOOL PIN COVER TO BE SURE IT

DOESN'T GET DAMAGED OR DAMAGE THE CASE. I PACK MOST WITH IT ON AND IF YOU

WANT TO LEAVE IT ON JUST MAKE SURE TO PUT ENOUGH PACKING ON TOP OF

MACHINE SO IT FITS SNUG WHEN YOU CLOSE THE LID.

JUST REMEMBER IF THE MACHINE IS IN A CARRING CASE, YOU WANT TO HAVE

ENOUGH PACKING IN AND AROUND THE MACHINE SO IT DOES NOT MOVE.

THIS IS MINOR DAMAGE, I DON'T HAVE A CASE AT THIS TIME WITH SOME

MAJOR DAMAGE BUT THIS LITTLE AMOUNT OF DAMAGE TO THE LID MAY

HAVE BENT OR BROKEN THE SPOOL PIN ON THE MACHINE.

I REPAIR THESE OLD MACHINES SO I BUY AND SELL A LOT OF THEM AND

I HAVE SEEN SOME REALLY POOR PACKING AND THERE IS NOTING WORSE

THAN TO SPEND $100+ ON A MACHINE THAT YOU PURCHASED AND GETTING

IT AND BECAUSE OF POOR PACKING THE MACHINE ARRIVES WITH DAMAGE

AND THE SELLER SAYS "YOU SHOULD HAVE PUT INSURANCE ON IT".

I WANT TO SAY TO EVERYBODY; "INSURANCE DOESN'T COVER DAMAGE

IT IS CAUSED BY POOR PACKING, THAT IS THE SELLER OR PACKING

COMPANY'S RESPONCEABILTY. INSURANCE IS PAYED IF THE SHIPPING

COMPANY IS RESPONCEABLITY FOR THE DAMAGE, OF COURSE THIS

MAY VERY DEPENDING ON WHO THE INSURER IS. WHAT I AM POINTING

OUT IS, IF YOU PACK IT WELL IT WILL ARRIVE IN THE SAME CONDITION AS

PURCHASED. TAKE YOUR MACHINE AND WRAP IT IN BUBBLE WRAP OR

WHAT EVER YOU HAVE.

DEPENDING ON THE CASE YOU MAY NEED TO TRIM WRAP SO MACHINE FITS INTO

CASE PROPER. THIS IS THE SMALL BUBBLES IF YOU ARE PACKING WITHOUT CASE

CAN USE THE BIGGER BUBBLES.

I TAKE PLASTIC OR PLASTIC BAG AND WRAP AROUND ATTACHMENT BOX AND THEN

RUN TAPE AROUND TO HELP SUPPORT THE BOX.

IF YOU HAVE OTHER ATTACHMENTS WRAP THEM AND YOU MAY BE ABLE TO FIT IN CASE UNDER THE SMALL TRAY

I ALSO PUT THE BOOK IN A PLATIC BAGGIE AND IF NEEDED PUT BETWEEN CARDBOARD

AND CAN BE PUT ALONG THE SIDE OF CASE. IF THE ATTACHMENTS WON'T FIT IN CASE WRAP AND PUT IN SHIPPING BOX.

THE FOOT CONTROL CAN GO AS SEEN OR WRAP WITH BUBBLE WRAP AND LAY ALONG THE BACK

CONTROL AND IF IT WILL FIT IN TRAY WILL PUT IT THERE OR LAY ALONG

SIDE OF MACHINE BELOW TRAY.

NOW THAT EVERYTHING IS PACKED SAFE IN THE CASE I TAKE MORE BUBBLE WRAP AND PACK

SIDES AROUND MACHINE AND ON TOP SO THAT WHEN I SHUT THE LID IT IS SNUG, NOW NOTHING

IS GOING TO MOVE WHILE BE SHIPPED.

TAKE SOME BUBBLE WRAP AND WRAP OUTSIDE OF CASE AND PUT A LITTLE UNDER HANDLE

TO PROTECT FROM LEAVING A MARK ON CASE.

AFTER YOU GET IT TAPED TAKE THE TAPE AND RUN A LINE ALL THE WAY AROUND IT TO HELP

SUPPORT LID AND CASE, I USUALLY RUN A LINE ON BOTH SIDE OF THE HANDLE.

PEANUTS OR PACKING OF YOUR CHOICE ON THE BOTTOM I LAY MACHINE IN ON IT'S SIDE

SET MACHINE IN BOX AND NOW PACK AROUND SIDES

WHAT I LIKE ABOUT PEANUTS IS IT GIVES THE MACHINE AN AIR RIDE BUT BALLED UP NEWS PAPER, PLASTIC BAGS FEEDBACK FROM MY CUSTOMERS ON MY PACKING AND THEIR BUYERS AS PURCHASED.

I HOPE THIS HELPS YOU AS A PACKER AND IF YOU ARE A BUYER OF MINE THAT IT GIVES YOU A PIECE OF MIND ON HOW YOUR PURCHASE WILL BE PACKED.

THANK YOU AND GOOD LUCK,

DUANE

301

THANK YOU FOR TAKING THE TIME AND I HOPE I WAS HELPFUL!!

If you have nay question please call or email me!

Call 1-605-359-8939

Where Do the Thread Go on Singer Touch Tronic 2010

Source: https://www.singeroriginalvintageproducts.com/page/497007648

0 Response to "Where Do the Thread Go on Singer Touch Tronic 2010"

ارسال یک نظر